As, Sb, Bi and other impurities are continuously enriched in the electrolyte during copper electrolysis, which affects the quality of cathode copper products. Therefore, the electrolyte must be regularly and quantitatively purified.

As, Sb, Bi and other impurities are continuously enriched in the electrolyte during copper electrolysis, which affects the quality of cathode copper products. Therefore, the electrolyte must be regularly and quantitatively purified.

The induction method will cause a large amount of copper loss, produce a large amount of acid mist, AsH3 and other toxic gases, and the copper powder produced needs to be treated by the back fire method, increasing energy consumption and pollution. The black copper slag produced is difficult to be comprehensively recycled.

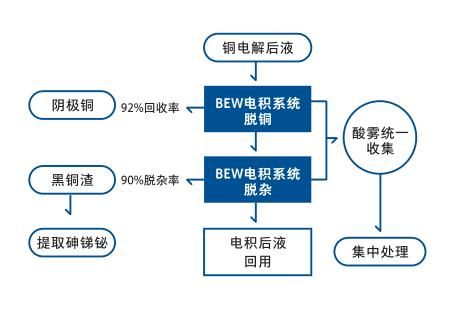

Compared with the traditional induced decopperization process, the turbulent electrowinning technology can reduce the output of black copper slag to 10% of the original process, so that more than 92% of copper in the purified liquid can be recovered as standard cathode copper. The removal rate of arsenic, antimony and bismuth is high. The black copper slag produced can be directly used for the extraction of arsenic, antimony and bismuth, avoiding the cyclic enrichment of these impurities in the system.

Back to top