Comprehensive recovery of valuable metals from zinc hydrometallurgy purification residue

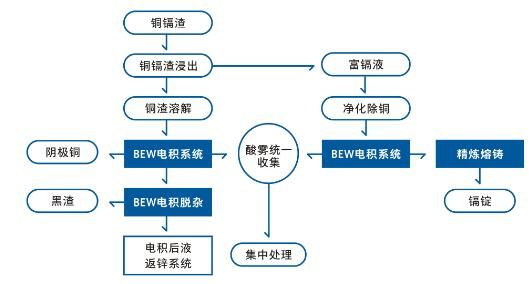

Utilizing its characteristics of resistance to fluoride and chlorine ions and selective precipitation, it can comprehensively recycle valuable metals in zinc hydrometallurgy purification bar.

The traditional recovery process has the disadvantages of high energy consumption, high pollution, complex process, low quality, low metal recovery rate, large consumption of auxiliary materials, large investment, etc. In addition, the small and medium-sized pyrometallurgical smelting method has been expressly prohibited. Since this slag exceeds the standard impurities of copper concentrate by tens to hundreds of times, it is unscientific to directly enter the copper smelting system.

The solid hazardous waste generated in the purification process of the zinc hydrometallurgy system mainly contains valuable metals such as Zn, Cu, Cd, Co, N, etc., with high recycling value.

The process conditions are simple, and the valuable metals in the leaching solution can be directly and efficiently recovered by one-step method.

The electrowinning solution can be returned to the zinc smelting system for recycling, so as to improve the recovery rate of the system.

The control is simple, and no additional chemical reagents need to be added.

National standard metal products are produced to remove a lot of impurities.

Back to top